Scan the WeChat code to contact us

Scan the WeChat code to contact us

Myco DIY: Sustainable Mycelium Grow Kit | Craft Biodegradable Wonders

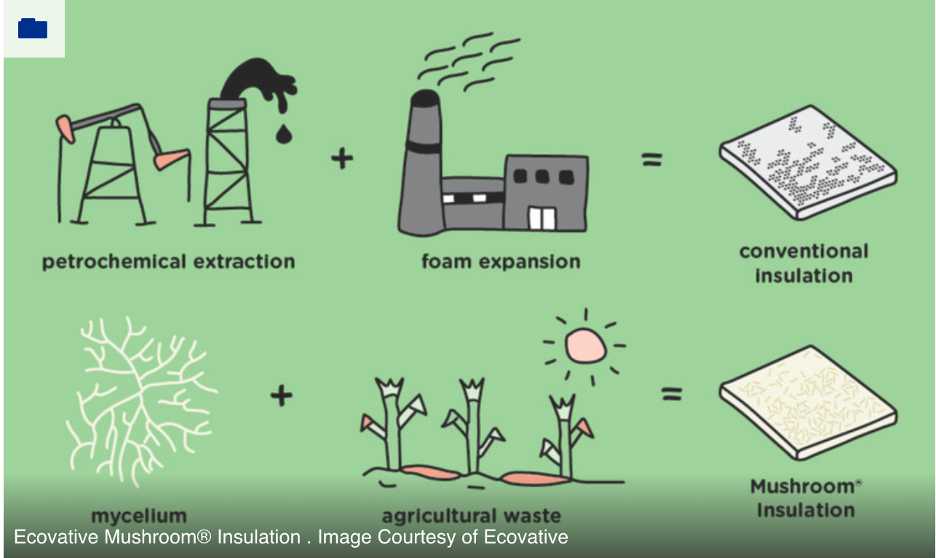

Bio-based materials like mycelium composites are emerging as revolutionary tools for architects tackling the construction industry’s massive carbon footprint—responsible for 38% of global CO₂ emissions (ArchDaily, 2022). By replacing traditional concrete and steel with low-carbon alternatives, these materials slash embodied carbon while enabling faster builds and lower logistics costs. From carbon-negative insulation to biodegradable structural panels, bio-based innovations are redefining sustainable construction.

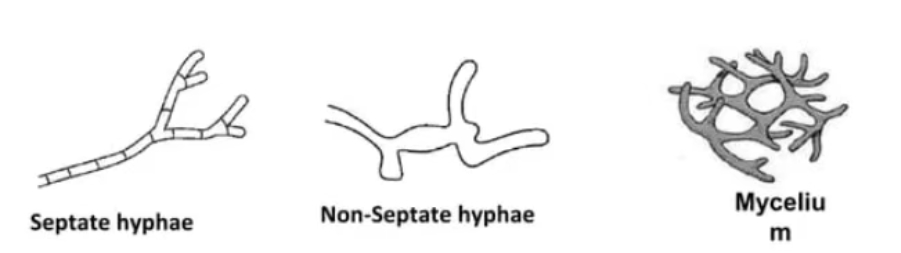

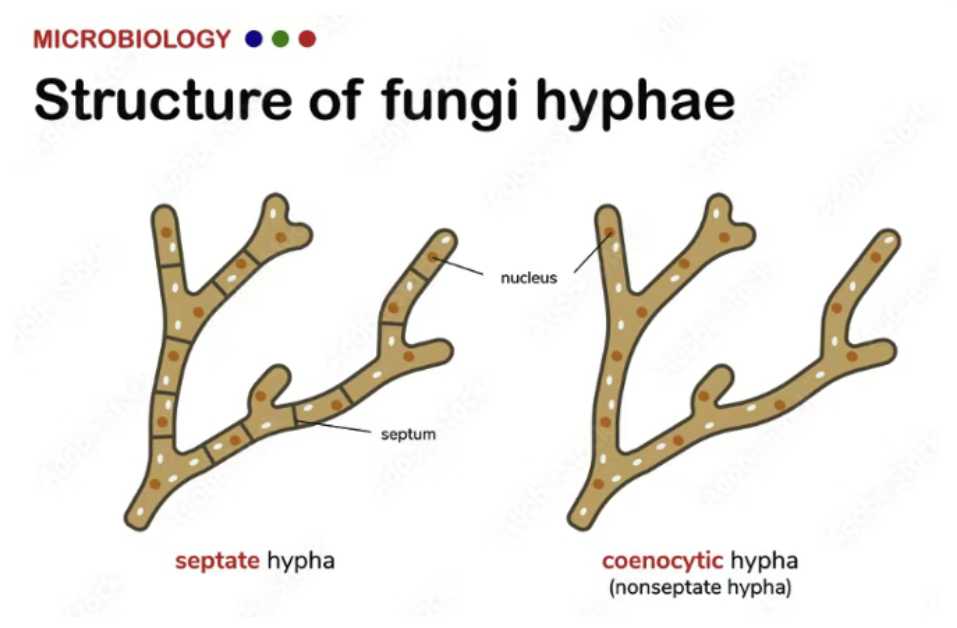

Mycelium—the root-like network of fungi—acts as nature’s decomposer, breaking down organic waste (wood, leaves, and even plastics) into nutrients. A single teaspoon of forest soil contains kilometers of mycelial filaments, capable of spanning a football field twice over. Unlike plants or animals, fungi belong to a unique biological kingdom, and their mycelium (composed of thread-like hyphae) secretes enzymes to digest organic matter.

| Comparison Item | Fungi | Mycelium |

|---|---|---|

| Role | Entire organism (biological Kingdom) | Nutrient-absorbing part of fungi |

| Visibility | Mushrooms visible; mycelium typically hidden | Requires microscopy or lab cultivation |

| Human Utilization | – Food (shiitake) – Medicine (penicillin) | – Sustainable building materials – Biodegradable packaging – Cultured meat substrate |

| Criteria | Mycelium-Based Materials | Traditional Materials (e.g., Concrete) |

|---|---|---|

| Carbon Emissions | 31 kg CO₂/m³ (low-carbon production) | 410 kg CO₂/m³ (high emissions) |

| Energy Consumption | Minimal energy (sterilization/drying), renewable options feasible | Fossil fuel-dependent (e.g., cement requires 1450°C kilns) |

| Biodegradability | 100% compostable (decomposes in months) | Non-biodegradable (takes centuries to degrade) |

| Raw Materials | Uses agricultural waste (rice husks, sawdust) | Requires mining (limestone, clay) |

| Structural Traits | Lightweight, excellent insulation, porous | High compressive strength, poor insulation |

| Lifespan | Ideal for temporary structures (5–10 years) | Long lifespan (50–100 years), but hard to recycle |

Companies like MycoWorks and Ecovative pioneer mycelium-based construction through a 4-step process: